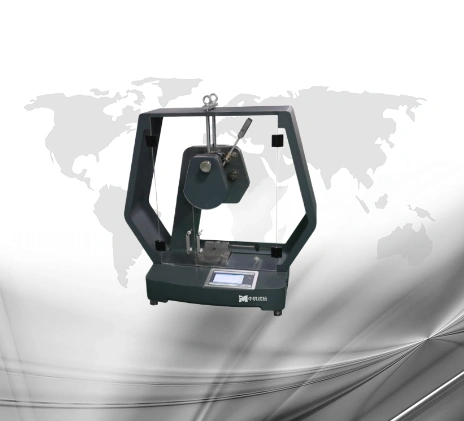

Touchscreen plastic pendulum impact testing machine DF53.550A

The new DF series plastic pendulum impact system is a state-of-the-art testing instrument, characterized by its high reliability, safety, and stability. Designed for assessing the impact resistance of non-metallic materials under dynamic loads, this system is ideal for testing plastics, nylon, hard rubber, fiberglass, and electrical insulation materials. The system is user-friendly, ensures high work efficiency, and automatically captures test data. Its versatility, supporting both simply supported beam (Charpy) and cantilever beam (Izod) tests, makes it an essential tool for manufacturers, quality inspection units, and research institutions.

Key Features:

-

High Reliability and Stability: Engineered for consistent and dependable performance.

-

Versatile Material Testing: Suitable for testing a wide range of non-metallic materials including plastics, nylon, hard rubber, fiberglass, and electrical insulation materials.

-

User-Friendly Operation: Designed for ease of use and efficient testing processes.

-

Automatic Data Acquisition: Automatically records test data after impact, reducing errors and improving data consistency.

-

High Work Efficiency: Enables high-throughput testing, making it suitable for continuous and extensive impact testing.

-

Dedicated Control Panel and Display: Provides a clear interface for displaying test data, including impact absorption energy, impact strength, and pendulum swing angle.

-

Integrated Test Report Printing: Allows for the easy generation and printing of test reports, streamlining record-keeping.

-

Dual Testing Capability: Supports both simply supported beam (Charpy) and cantilever beam (Izod) impact tests.

-

Adjustable and Replaceable Supports: Designed for easy adjustment and replacement of supports, offering strong applicability for various testing standards.

Main Parameters:

1. Impact Energy:

-

Simply Supported Beam (ISO/GB): 5J

-

Simply Supported Beam (ASTM): 5.4J

-

Cantilever Beam: 5.5J

2. Angle Resolution:

-

0.045º

3. Simply Supported Beam (ISO/GB):

-

Impact Speed: 2.9 m/s

-

Pre-Swing Angle: 107º

-

Distance from Pendulum Axis to Specimen Center: 330 mm

-

Impact Blade Angle: 30º

-

Impact Blade Rounding Radius: 2 mm

-

Support Rounding Radius: 1 mm

-

Support Front Angle: 5º

-

Support Rear Angle: 10º

-

Support Span: 62 mm

-

Specimen Size (Length x Width x Thickness): 80 mm x 10 mm x 4 mm

4. Simply Supported Beam (ASTM):

-

Impact Speed: 3.46 m/s

-

Pre-Swing Angle: 148º

-

Distance from Pendulum Axis to Specimen Center: 330 mm

-

Impact Blade Angle: 45º

-

Impact Blade Rounding Radius: 3.17 mm

-

Support Rounding Radius: 3.17 mm

-

Support Span: 101.6 mm

-

Specimen Sizes (Length x Width x Thickness):

-

127 mm x 12.7 mm x 3.17 mm

-

127 mm x 12.7 mm x 6.35 mm

-

127 mm x 12.7 mm x 12.7 mm

-

5. Cantilever Beam (Izod):

-

Impact Speed: 3.5 m/s

-

Pre-Swing Angle: 148º

-

Distance from Pendulum Axis to Specimen Center: 330 mm

-

Blade Rounding Radius: 0.8 mm

-

Distance from Blade Center to Upper Surface of Jaw:

-

ISO/GB: 22 ± 0.2 mm

-

ASTM: 22 ± 0.05 mm

-

-

Specimen Sizes (Length x Width x Thickness):

-

ISO/GB: 80 mm x 10 mm x 4 mm

-

ASTM:

-

63.5 mm x 12.7 mm x 12.7 mm

-

63.5 mm x 12.7 mm x 6.4 mm

-

63.5 mm x 12.7 mm x 3.2 mm

-

-

6. Environmental Parameters:

-

Ambient Temperature: 10 to 35 °C

7. Physical Dimensions:

-

Host Dimensions (Width x Height x Depth): Approx. 760 mm x 800 mm x 520 mm

-

Dimensions with Protective Cover (Width x Height x Depth): Approx. 1050 mm x 1030 mm x 520 mm

-

Weight (with Protective Cover): Approx. 210 kg

8. Power Supply:

-

Host Power Supply: Single-phase 100V-240V, 50Hz, 0.1kW

9. Environmental Conditions:

-

Must be free of corrosive media, vibration, and strong electromagnetic field interference.

Key Selling Points Highlighted:

-

Versatility: Supports both Charpy and Izod impact tests.

-

High Precision: Accurate and reliable measurements due to high-resolution angle measurement.

-

Automation: Automatic data acquisition and streamlined operation enhance efficiency.

-

Robust Construction: Ensures consistent performance and longevity.

-

User-Friendly Interface: Easy to learn and operate with a dedicated control panel and display.

-

Comprehensive Safety: Includes a protective cover for user safety.

-

Wide Application: Ideal for various industries and research purposes.