JSW-JL-450M Falling Mass Impact Testing Machine

- Functions:

It is suitable for the determination of impact toughness of PVC-U, PVC-C, PP, PE and plastic pipes used in underground communication pipes. Is the testing, production units, building materials industry, scientific research units ideal testing equipment. The control part of the testing machine is controlled by PLC, the touch screen operation shows a high degree of automation, the height of impact, Hammer and drop hammer can be preset and displayed digitally, and the pneumatic transmission device is used to prevent the second impact, the second impact capture rate is 100% . Equipped with personal safety automatic protection device (sample room door safety protection, anti-electric shock safety protection) . The instrument is easy to operate, safe and reliable, beautiful appearance, exported to Europe and the United States and other countries

- standards-compliant:

ASTMD 2444

JB/T 9389

- 3.Características del producto

- Tertiary protection

Safety protection of the hatch of the first level sample cabin; Second level observation window and door safety protection; The third level of upper and lower limit safety protection.

- Rapid lifting

Using high torque stepping motor, the rising rate can reach 250mm / sec, which can be achieved in 8 seconds from zero to 2m.

- Intelligent hovering

The machine adopts multi-stage speed control program to ensure that the hammer stops smoothly and the control position has no deviation.

- Exhaust pipe modeling

The drop hammer pipe adopts 3D modeling, and the exhaust hole is added to minimize the wind resistance. At the same time, the hoop structure of the pipe is added to prevent the failure and deformation of the pipe.

- Gas connection and gas discharge

Abandon the traditional electromagnet hammer connection and electromagnet hammer release, and adopt the pneumatic structure with greater force value and never burn. The hammer connection adopts 300N long stroke double cylinders and the hammer connection surface of ox tendon plate, which is stable and does not damage the hammer head; The pneumatic structure is also adopted for the drop hammer, which fundamentally solves the phenomenon of long-time bending, wire breaking and electric leakage of the cable used in the electromagnet drop hammer. Pneumatic adopts airless automatic locking structure, which is safe and reliable.

- Integrated modular assembly

The mechanical part adopts standard aluminum alloy profile assembly structure, and the electrical part adopts 7-inch touch screen and Delta PLC, which realizes the characteristics of process standardization, modular installation, light structure and high strength.

- High degree of automation

The instrument can automatically zero, automatically grasp the hammer, automatically lift the hammer and automatically test.

- Technological indicators:

Impact height: 10-3000mm,±2mm

Overall dimensions: L730mm×W700mm×H4520 mm

Energy losses: 0.25%

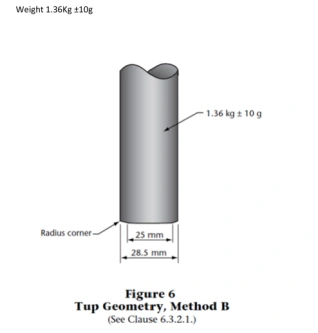

weights (customized by customers), permissible tolerance shall be ±0.5%

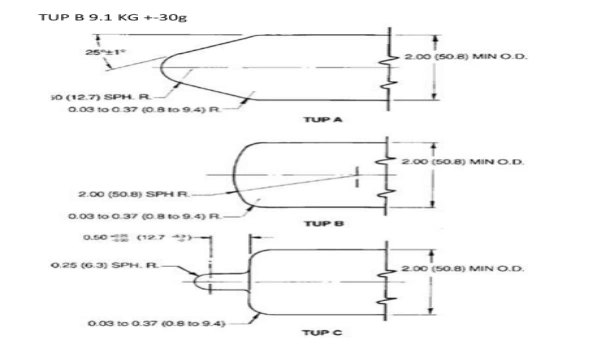

Nose and masses of striker: depending on customers standards

Anti-rebound catching rate: 100%

Test specimen: 10mm-450mm

Weight:500KG